We just learned about the

sledgehammer.

Sometimes when a blacksmith needs to cut a piece of metal, they will use something called a

chisel.

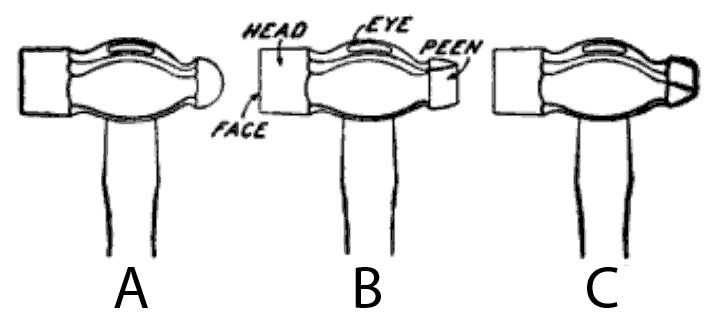

There are two main types of chisels, a hot chisel or cold chisel.

A cold chisel is used for metal that is cooled down, and is sometimes used to put marks or grooves in metal.

A hot chisel is used for metal that has been in the forge and is very hot.

A blacksmith will hold the chisel over the metal, and then hit the top of the chisel with the hammer.

There is a special type of chisel called the hotcut hardy, which goes into an anvil's hardy hole.

The point of the hotcut hardy chisel is facing up, and the blacksmith puts the metal on the top of the chisel and hits the metal, pushing it into the pointed part of the chisel.

(from: wikipedia -

chisel)

Kid Facts - Blast from the past: Freezing Rain