We've just learned about what a metal

Burr is.

Another way to work with metal is

Bending.

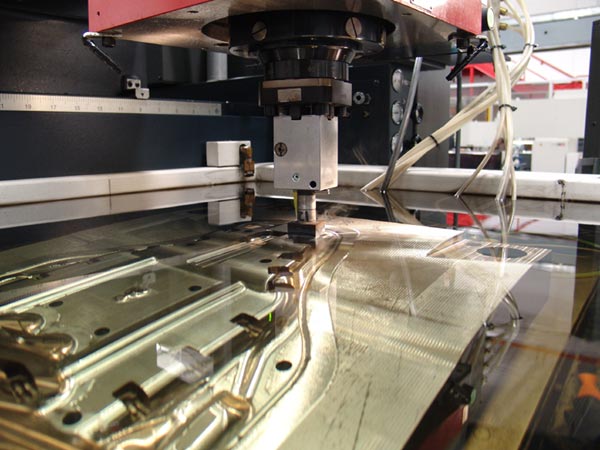

Sometimes if you have a long metal pipe or sheet of metal that you want to be bent in a certain way, you have to use a tool or machine to get the exact bend you want.

You might want a nice rounded curve, or you might want a V shaped bend of exactly the right size.

There are different types of bends that you can make, everything from air bending, bottoming, coining, three-point bending, folding, wiping, rotary bending, roll bending, elastomer bending, joggling.

There are many types of machines to do all different types of bends, like a cornice brake, box-and-pan brake, bar folder, press brake, punch press, screw press and stamping press.

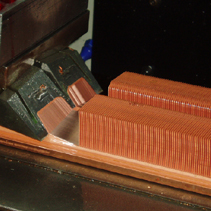

Many of the tools use something called a "die" which is something with a special shape used to bend the metal the way you want. There are many dies out there, like v, rotary bending, 90 degree, acute angle, gooseneck, offset, hemming, seaming, radius, beading, curling, tube and pipe forming, four-way, channel-forming, u-bend, box-forming, corrugating, multiple-bend and rocker!

Basically any way you want to bend your metal, there is a tool and die for it!

(from: wikipedia -

bending (metalworking))

(from: wikipedia -

brake (sheet metal bending))

(from: wikipedia -

press brake)

Kid Facts - Blast from the past: Anvil