We just learned about the Skiving Machine.

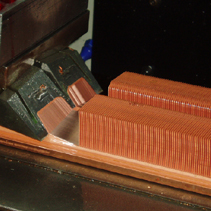

Another type of metal working is called Threading.

If you've ever seen a nut that spins onto a bolt, you've seen something made by a tap and die.

The nut has to be cut exactly right to fit onto the screw, or else it won't screw on.

The tap is the tool that cuts the hole into the nut or other hole where the screw will go.

The die is the tool that cuts the lines onto the screw so it fits into the nut.

There are hand taps and dies that you can use with just your hands if you are strong enough, or there are machines that use strong motors to cut into the metal.

(from: wikipedia - nut (hardware))

(from: wikipedia - tap and die)

Kid Facts - Blast from the past: Category 1 Hurricane